This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

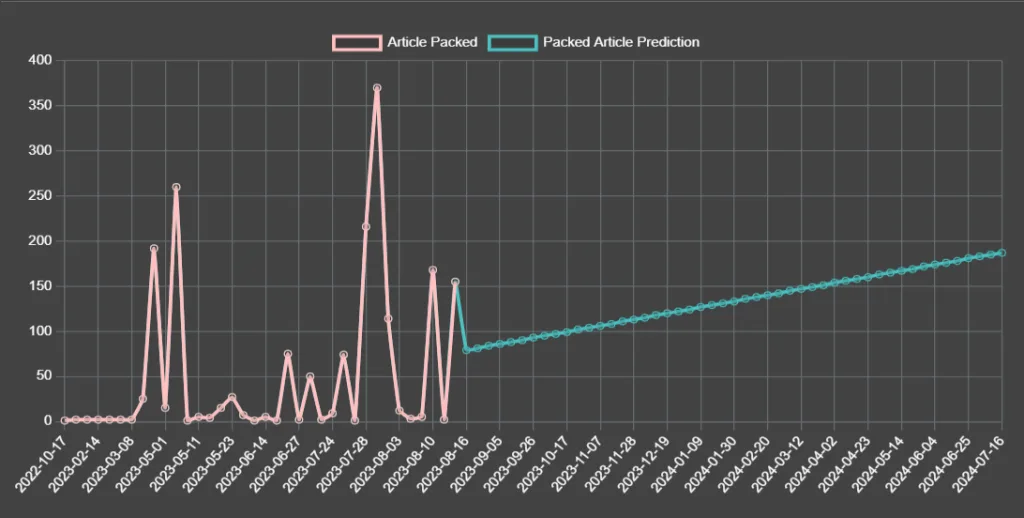

AI/ML Predictions by pakaneo for Best Packing Calculations

In current AI world, pakaneo has expelled his software to packing products predictions for their users. We always making our software rich by features and latest trends.

In current AI world, pakaneo has expelled his software to packing products predictions for their users. We always making our software rich by features and latest trends.

Predictions

- Demand Forecasting and Inventory Optimization: AI and ML can help WMS systems analyze historical data and external factors to improve demand forecasting accuracy. This can lead to better inventory management, reduced stockouts, and optimized replenishment strategies.

- Predictive Maintenance: AI-powered WMS can predict equipment failures and maintenance needs based on sensor data and usage patterns. This can reduce downtime and improve overall operational efficiency.

- Route Optimization: ML algorithms can analyze real-time data about order volumes, traffic conditions, and delivery constraints to optimize picking and shipping routes. This results in faster and more efficient order fulfillment.

- Automated Picking and Packing: AI and robotics integration can enable automated picking and packing processes. Computer vision and robotics can work together to identify items, pick them from shelves, and pack them efficiently.

- Real-time Visibility and Tracking: AI-enhanced WMS can provide real-time visibility into inventory levels and movement throughout the supply chain. ML algorithms can predict potential delays or disruptions and recommend proactive actions.

- Cognitive Search and Natural Language Processing: AI-powered WMS can incorporate natural language processing to enhance search capabilities. This could allow warehouse staff to ask questions or issue commands in natural language, improving user experience and operational efficiency.

- Quality Control: AI can assist in quality control by analyzing images of products to identify defects or inconsistencies. This can reduce errors in picking and packing, ensuring higher customer satisfaction.

- Adaptive WMS: ML algorithms can continuously learn from operational data and adjust parameters to adapt to changing business needs. This leads to systems that become more efficient and effective over time.

- Risk Management: AI can identify potential risks in the supply chain, such as supplier disruptions or regulatory changes, and suggest strategies to mitigate these risks.

- Personalized Customer Experience: AI can analyze customer behavior and preferences to personalize the order fulfillment process. This could include recommending related products, suggesting optimal delivery times, or offering tailored promotions.

- Human-Machine Collaboration: AI and ML will likely facilitate smoother collaboration between human workers and automated systems. This could involve using wearable devices that provide real-time information to workers, guiding them to specific locations or tasks.

Checkout our best post on Picking Visuals Strategies - pakaneo Software Exploring Maximum User Friendliness with 3 Best Approaches